Question: 3. (20 points) The continuous stopwatch timing method was used to obtain the observed times for a worker machine task. Only one cycle was timed.

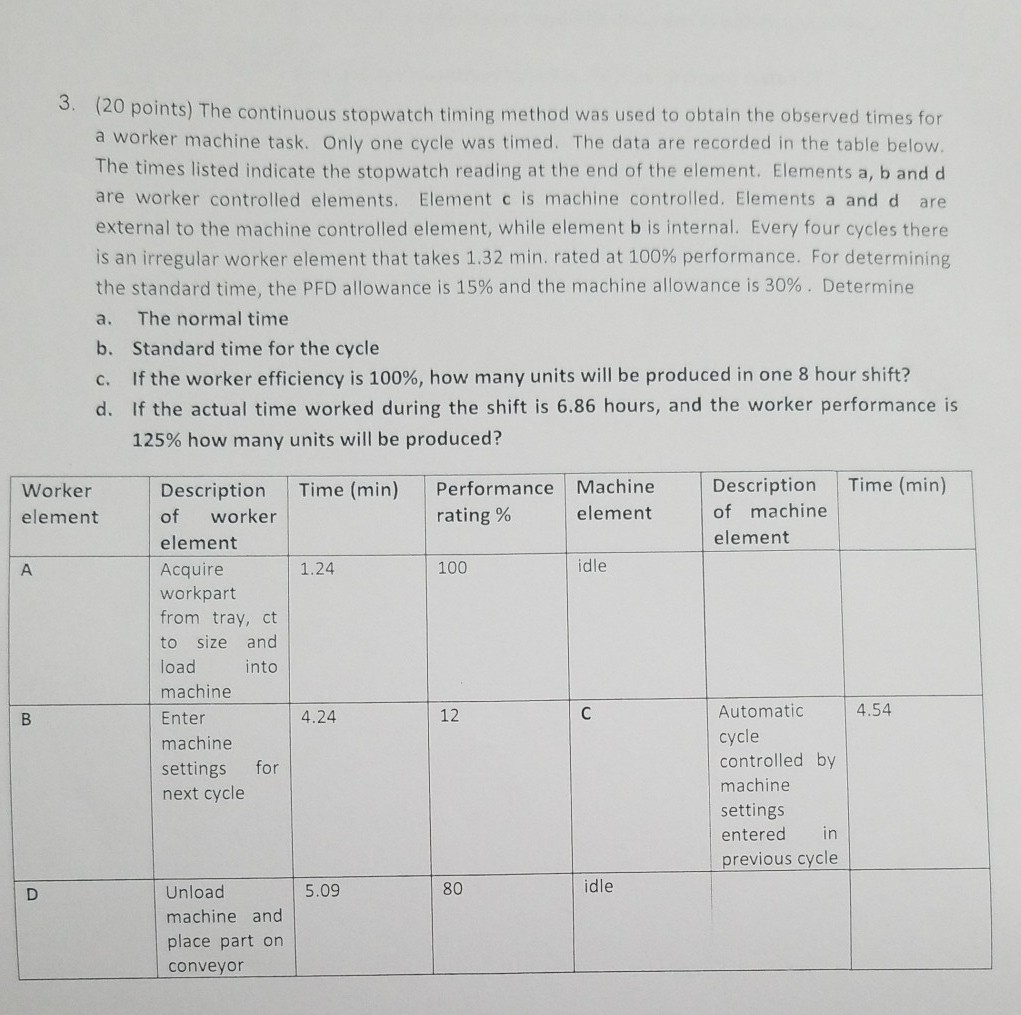

3. (20 points) The continuous stopwatch timing method was used to obtain the observed times for a worker machine task. Only one cycle was timed. The data are recorded in the table below. The times listed indicate the stopwatch reading at the end of the element. Elements a, b and d are worker controlled elements. Element c is machine controlled. Elements a and d are external to the machine controlled element, while element b is internal. Every four cycles there is an irregular worker element that takes 1.32 min. rated at 100% performance. For determining the standard time, the PFD allowance is 15% and the machine allowance is 30%. Determine The normal time . b. Standard time for the cycle If the worker efficiency is 100 % , how many units will be produced in one 8 hour shift? C. d. If the actual time worked during the shift is 6.86 hours, and the worker performance is 125% how many units will be produced? Time (min) Description Machine Time (min) Performance Worker Description of machine element rating % element of worker element element idle 100 1.24 Acquire workpart from tray, ct A size and to load into machine Automatic 4.54 Enter 4.24 cycle controlled by machine for settings machine next cycle settings in entered previous cycle idle 80 Unload 5.09 D machine and place part on conveyor 12 3. (20 points) The continuous stopwatch timing method was used to obtain the observed times for a worker machine task. Only one cycle was timed. The data are recorded in the table below. The times listed indicate the stopwatch reading at the end of the element. Elements a, b and d are worker controlled elements. Element c is machine controlled. Elements a and d are external to the machine controlled element, while element b is internal. Every four cycles there is an irregular worker element that takes 1.32 min. rated at 100% performance. For determining the standard time, the PFD allowance is 15% and the machine allowance is 30%. Determine The normal time . b. Standard time for the cycle If the worker efficiency is 100 % , how many units will be produced in one 8 hour shift? C. d. If the actual time worked during the shift is 6.86 hours, and the worker performance is 125% how many units will be produced? Time (min) Description Machine Time (min) Performance Worker Description of machine element rating % element of worker element element idle 100 1.24 Acquire workpart from tray, ct A size and to load into machine Automatic 4.54 Enter 4.24 cycle controlled by machine for settings machine next cycle settings in entered previous cycle idle 80 Unload 5.09 D machine and place part on conveyor 12

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts