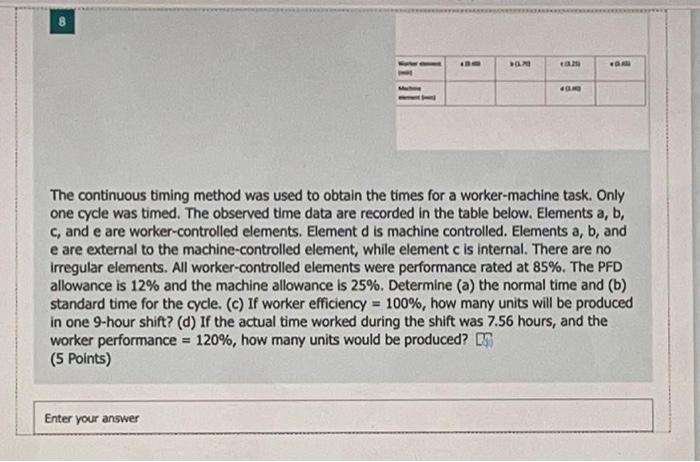

Question: 8 ! DO The continuous timing method was used to obtain the times for a worker-machine task. Only one cycle was timed. The observed time

8 ! DO The continuous timing method was used to obtain the times for a worker-machine task. Only one cycle was timed. The observed time data are recorded in the table below. Elements a, b, c, and e are worker-controlled elements. Element d is machine controlled. Elements a, b, and e are external to the machine-controlled element, while element c is internal. There are no irregular elements. All worker-controlled elements were performance rated at 85%. The PFD allowance is 12% and the machine allowance is 25%. Determine (a) the normal time and (b) standard time for the cycle. (c) If worker efficiency = 100%, how many units will be produced in one 9-hour shift? (d) If the actual time worked during the shift was 7.56 hours, and the worker performance = 120%, how many units would be produced? 68 (5 Points) Enter your answer A total of 10 cycles have been observed during a direct time study. The mean for the largest element time = 1.40 min, and the corresponding sample standard deviation s = 0.15 min. (a) Based on these data, what is the 95% confidence interval on the 1.40 min element time? (b) If the analyst wants to be 98% confident that the mean of the sample was within +- 5% of the true mean, how many more observations should be taken? DS (5 Points) 8 ! DO The continuous timing method was used to obtain the times for a worker-machine task. Only one cycle was timed. The observed time data are recorded in the table below. Elements a, b, c, and e are worker-controlled elements. Element d is machine controlled. Elements a, b, and e are external to the machine-controlled element, while element c is internal. There are no irregular elements. All worker-controlled elements were performance rated at 85%. The PFD allowance is 12% and the machine allowance is 25%. Determine (a) the normal time and (b) standard time for the cycle. (c) If worker efficiency = 100%, how many units will be produced in one 9-hour shift? (d) If the actual time worked during the shift was 7.56 hours, and the worker performance = 120%, how many units would be produced? 68 (5 Points) Enter your answer A total of 10 cycles have been observed during a direct time study. The mean for the largest element time = 1.40 min, and the corresponding sample standard deviation s = 0.15 min. (a) Based on these data, what is the 95% confidence interval on the 1.40 min element time? (b) If the analyst wants to be 98% confident that the mean of the sample was within +- 5% of the true mean, how many more observations should be taken? DS (5 Points)