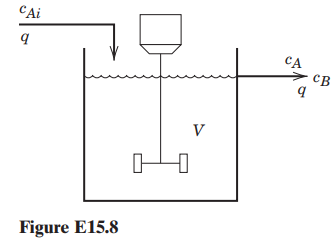

Question: A liquid-phase reversible reaction, A B, takes place isothermally in the continuous stirred-tank reactor shown in Fig. E15.8. The inlet stream does not contain any

![moles of A reacting (time) (volume) -ra = k,cA – k,Cg, ľA [=]](https://dsd5zvtm8ll6.cloudfront.net/si.question.images/images/question_images/1533/6/3/8/1385b6975fa387a71533620388738.jpg)

The control objective is to control exit concentration cB by manipulating volumetric flow rate, q. The chief disturbance variable is feed concentration cAi. It can be measured on-line, but the exit stream composition cannot. The control valve and sensor-transmitter have negligible dynamics and positive steady-state gains

(a) Design a feedforward controller based on a dynamic model.

(b) If the exit concentration cB could be measured and used or feedback control, should this feedback controller be reverse- or direct-acting?

(c) Is dynamic compensation necessary?

moles of A reacting (time) (volume) -ra = k,cA k,Cg, A [=] CAi CA > CB Figure E15.8

Step by Step Solution

3.31 Rating (163 Votes )

There are 3 Steps involved in it

a Feedforward controller design A dynamic model will be developed based on the following assumptions ... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (2 attachments)

1602_606321ef1a26d_680404.pdf

180 KBs PDF File

1602_606321ef1a26d_680404.docx

120 KBs Word File